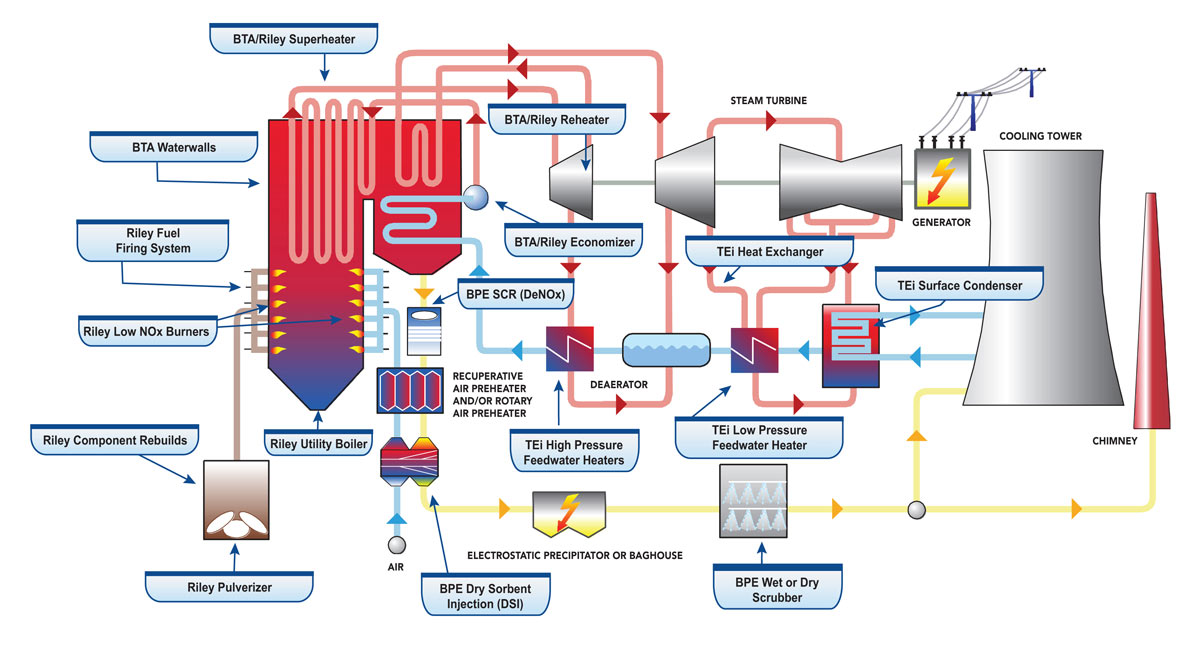

Coal Power Plant

Improve Efficiency, Operation and Consumption with the Goal of Reducing Operation & Maintenance Spending

We design SCRs to be fully integrated with the boiler to ensure seamless operations. Our complete integrated SCR systems are comprised of Computational Fluid Dynamics (CFD) and physical modeling, ductwork, reactors, support steel, initial catalyst charge, fans, complete reagent loading, storage, injection systems, startup, testing, and training.

SCR Design Features include:

- Two four layer reactors per unit

- Three initially installed layer and one future layer of catalyst

- Inlet and outlet NOx analyzers

- SCR inlet temperature control (per reactor)

- Two double louver economizer bypass dampers

- One single louver backpressure damper

- Delta Wing™ static mixers with six ammonia injectors

- Six sonic horns per installed catalyst layer

For applications that require relatively low removal efficiencies (less than 90%), we offer the Delta DSI solution. Delta DSI is a lower capital cost system that can be used to remove acid gas constituents including SO2, SO3, HCI, and mercury.

This is a cost-effective, highly efficient system designed to remove acid gas constituents. The Turbosorp® Circulating Dry Fluid Bed Scrubber is a cost effective, highly efficient system designed to remove acid gas constituents, including SO2, SO3, HCl, HF, mercury, and other trace pollutants from flue gas streams. Turbosorp® is ideally suited for coals with sulfur contents greater than 3.0%, and typically results in acid gas removal efficiencies greater than 97%.

RSCR® System is designed to reduce NOx and other emissions from boilers and process equipment, targeting tail-end/low temperature applications where the flue gas is relatively cool with low levels of particulates and acid gases.

We provide flue gas desulfurization systems to the power generation industry where applications require high efficieny SO2 removal while still effectively managing power consumption.

People, Availability, and Quality of Deliverables

Our natural circulation steam generators fire a wide range of coals and other fossil fuels.

We offer commissioning services for any boiler or boiler-related equipment. We furnish qualified field engineers to assist in start-up and commissioning of your steam generating, fuel burning, and environmental equipment.

DESIGN SOLUTIONS FOR ALL YOUR HEAT TRANSFER EQUIPMENT

Steam Surface Condenser

Our condenser designs can incorporate enhanced deareation systems, and/or a variety of turbine exhaust options, which can assist in improving plant layouts. We continually address and refine these and other considerations associated with circular designs where space is at a premium. The surface condenser is a critical component in the operation of a steam power plant. Condenser failures can result in forced outages and loss of generation capacity. TEi condensers represent an evolution of advanced technology, offering improved thermal efficiency and advanced mechanical design to reduce forced outages and increase availability.

Steam Surface Condenser, Modular Changeouts

As the innovator in heat transfer technology, TEi provides exceptional modular changeout options for steam surface condensers. Modular changeouts are an efficient alternative to the conventional retube. Existing condensers can be refurbished, redesigned, and even upgraded to meet new performance demands and power requirements. Complete surface condenser retrofits are possible and can offer a multitude of benefits. A surface condenser is critical to the efficient operation of a power plant.

Low Pressure Feedwater Heater

Each feedwater heater can extract up to 30% of the turbine throttle steam and is designed to specific thermal conditions and manufactured for a singular purpose. The low pressure feedwater heaters play a key role in maintaining efficient, trouble-free operation of your generation facility and the vertical channel down (VCD) designs offer a small footprint, piping economics and simplified bundle access.

High Pressure Feedwater Heater

TEI’s feedwater heaters are each designed to specific thermal conditions and manufactured for a singular purpose. Whether it be sophisticated designs involving extreme superheat, abnormal flow conditions or dissipation of high energy fluids, TEi has the expertise and experience to offer proven solutions to any design problem. TEi provides innovative and practical concepts to ensure peak heater performance from installation to testing through full or part-load operation. We offer a multitude of design configurations for desuperheater and drains cooler zones as well as the latest in channel closure techniques. The three most common are listed below:

∙ Bolted-Gasketed Closure – This economical, gasketed pill box is easily disassembled for full access.

∙ Seal-Welded Diaphragm Closure – This economical welded closure is leak-proof and easily disassembled for full access. It requires no gaskets.

∙ Breech-Lock Closure – This widely accepted, quick opening closure provides full access to the tubesheet and structural reliability under varying temperature and pressure conditions.

Closed Cycle Cooling Water HX

TEi has successfully supplied numerous optimized BOP and CCW designs for numerous fossil and nuclear power plants undergoing power up-rates and routinely provides solutions for power plants needing to improve efficiencies. With diverse high-quality applications, impressed current & galvanic anodic protection, elimination of potential cross-contamination of fluids, compact construction when designing for fluids with high thermal resistances and can be externally and internally applied, TEi’s mission-critical equipment helps ensure a stable, optimal operating temperature while reducing costs and dramatically improving efficiencies for our customers.

Generator Cooler HX

TEi’s Generator Engine Coolers cool air or hydrogen, which in turn cools the internal components of the motor or generator. These coolers are available in single tube, double tube, plate-fin and fin-tube designs.

Lube Oil Cooler HX

The lube oil cooler is to manitain oil temperature of the turbine lube oil by utilizing cooling water through the tubes. TEi provides shell & tube TEMA type heat exchangers for this service.

Motor Cooler HX

TEi’s Motor Coolers cool air or hydrogen, which in turn cools the internal components of the motor or generator. These coolers are available in single tube, double tube, plate-fin and fin-tube designs.

TOP PEOPLE, REGIONAL LOCATIONS, WE DELIVER

TEIC Construction Services leads the industry with more than 20 years’ experience in providing direct-hire, on-site construction services for the installation, repair, alteration and maintenance of boilers and boiler-related power plant equipment nationally. Our services include:

• Gas Conversions

• Ash Dewatering Systems

• Auxiliary Boiler Installation

• Environmental Control Systems